PRODUCT DETAILS

Alloy Wheel Repair London’s Cracked Alloy Wheel Repair Service

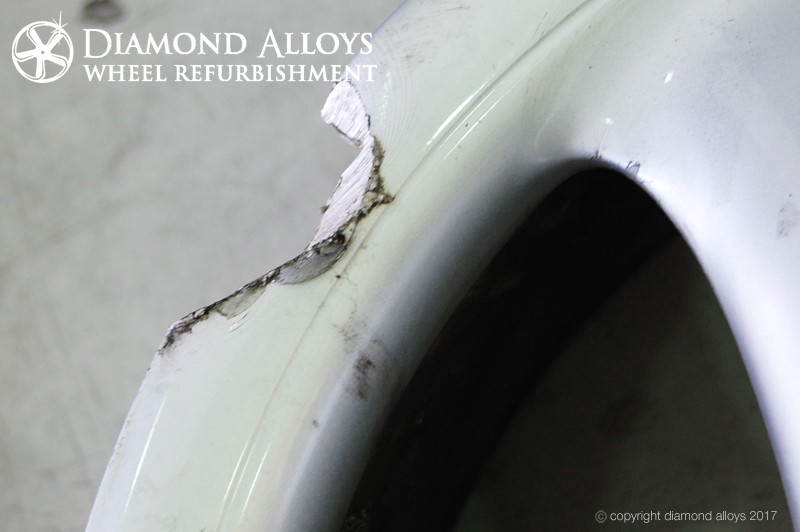

Driving over potholes and speed bumps is often enough to crack alloy wheels. The fact that the size of the wheel and the tyre combined is the same on all cars means that larger alloys have lower profile sidewalls, and these may be more prone to cracking. This happens because the sidewall of the tyre must flex to absorb various impacts, meaning that the smaller the sidewall, the less flexing ability the tyre has. Larger alloys are far more likely to sustain damage from the likes of speed bumps, kerbs and potholes.

Having a crack in an alloy doesn’t necessarily mean that you have to deal with the significant expense of buying a new alloy. Our alloy welding repair service means that we can repair hairline cracks for a tiny percentage of the cost of buying new alloys.

Our experts will examine your alloys for defects such as kerb damage, stress fractures and cracks. Our cracked alloy repair expertise is such that we can even replace larger missing chunks, and most of the alloy wheel welding we do can be completed in 24 hours. Once we’ve worked on your tyres, they will be completely safe and can be balanced, one of the services we provide at Alloy Wheel Repair London.

Spotting a Crack in Your Alloy Wheels

Most cracks only come to light following the discovery of a slow puncture. Checking the pressure of your tyres on a regular basis will help to alert you to the presence of any invisible hairline cracks which are letting air out. If you have any doubts, bring your car to us and we’ll look at it for you.

Is A Crack Repair Alloy as Good as a new Replacement?

We believe it’s every bit as good! Welding the cracks is a simple process which preserves the integrity and strength of the wheel. The cracked alloy repair can be combined with refurbishment to completely revamp the alloy. The application of a powder coat will make is so that there’s simply no sign of the original damage. The cost for the repair depends upon the number of cracks in the alloy and how severe they are, although it will still cost less than buying a new alloy, and we always provide a full quote before starting work.

Alloy Wheel Welding – How it Works

Every alloy is checked thoroughly for buckles and cracks, so if we note any problems when the tyres arrive with us, we’ll let you know. If we find a crack or large chip, we handle it as follows:

1. The Wheels Come at Alloy Wheel Repair London Workshop

Wheels can be dropped off by customers or we can collect them ourselves. Once they arrive, the tyres will be removed using specialist equipment. Identifying marks are applied, and the tyres safely stored.

We check the alloys for stress fractures, buckles or cracks, and let the customer know if they are beyond repair or not safe to drive on. At this stage we will advise whether any work besides the buckled wheel repair itself needs to be carried out. The next stage is to strip the weights from the wheels and mark them using tyre pressure sensor equipment to guarantee the right replacement.

2. Aquablasting

Chemicals are used to strip the alloys back to bare metal, after which aquablasting is used to remove chemicals, other impurities while keying the alloy’s surface. This part of our custom alloy wheel repair service works more quickly than other methods and delivers the best results. The next stage is for the alloys to be de-greased and carefully removal of any damage to your wheels with abrasive discs. Following this any damage to the rim edges and face will be prepared, dressed and filled to be dealt with.

3. Welding

Initially, contamination is removed from the crack by grinding out both sides, offering the perfect conditions for welding. Both sides of the alloy wheel are then welded to guarantee the strongest possible weld. Once the welding has been done, the wheel will be as good as new, and the weld will be ground down to protect the interior of the tyre.

4. Powder Primer is Applied

The alloys being worked on are then placed in an oven and heated for 30 minutes. This removes any air trapped in the microscopic pores, so that no air escapes as the paint is being applied, something which could reduce the quality of the finish.

Powder primer is now applied to every side of each section and the alloys are reheated to make sure that the powder primer is cured to produce a high strength, hard wearing coating.

5.The Finished Colour

The colour of your choosing can now be applied to the alloys. This could be a standard finish, a diamond cut finish or a custom finish. In all cases a final coat of lacquer is applied to the alloys and then they are baked. This will result in a durable item capable of dealing with the elements.

After being baked, the alloy sections are hung up to cool for approximately 20-30 minutes, before being inspected to check that they meet our extremely high standards.

6. Tyres are Re-fitted and Balanced

The last thing we do is reassemble the split rim and refit the tyres, before balancing the wheels and, if possible, resetting any tyre pressure system. Following this the wheels are ready to be collected.

Please note that we will not refit illegal tyres.

Alloy Wheel Welding – Common Questions

- How can I spot a cracked wheel?

You may be told your wheel is cracked during a MOT, when they are being refurbished or when new tyres are being fitted. If the air seems to be leaving your tyres more quickly than usual, then this may indicate the presence of a hairline crack. - Does a cracked wheel have to be replaced with a new wheel?

It does not, since wheel welding will repair the wheel for a tiny percentage of the cost of replacing it. - Can more than one crack be repaired?

Yes, it can, although we usually limit welding to three cracks per wheel. - Is it possible to repair split rim alloy wheels?

Yes, we can repair split rim alloys. - Will the strength of the wheel be reduced after welding?

Although the strength of the wheel won’t be compromised, the poor state of the UK roads means that further damage can’t be ruled out. The best way to avoid this is to steer clear of potholes entirely or drive over them slowly and carefully. - What if the wheel is buckled as well?

We can fix the buckle while we do the welding. - Is it possible to refurbish the wheel to match the existing finish?

In most cases we can match the existing finish for you. - Is there anything else I need to know?

We provide a stress-free 48-hour service.

More than one crack per wheel leads to a discount price.