PRODUCT DETAILS

Diamond Cut Wheel Refurbishment

Our diamond cut alloy service provides a high-quality service offering the best finish for any alloy wheels. Using a precision cut on the rim means only the minimum of material is removed, increasing the number of cuts which can be applied. This sets out diamond cut alloy repair apart from other types of refurbishment.

The diamond cut alloy repair process begins with the removal of grit, tar and dirt using a specialist aqua jet machine. This enables our experts to take a closer look at the tyre and decide exactly which processes need to be carried out. The next stage is for the clean wheel to be powder coated and then precision cut using a lathe, which results in a high cut, high shine appearance.

The final stage of a diamond cut alloy repair is for a scratch proof lacquer coating to be applied and the wheel baked in an alloy wheel oven. Our experts will then check the alloys to ensure that they meet our extremely high standards, before refitting them, inflating them to the intended pressure and rebalancing them.

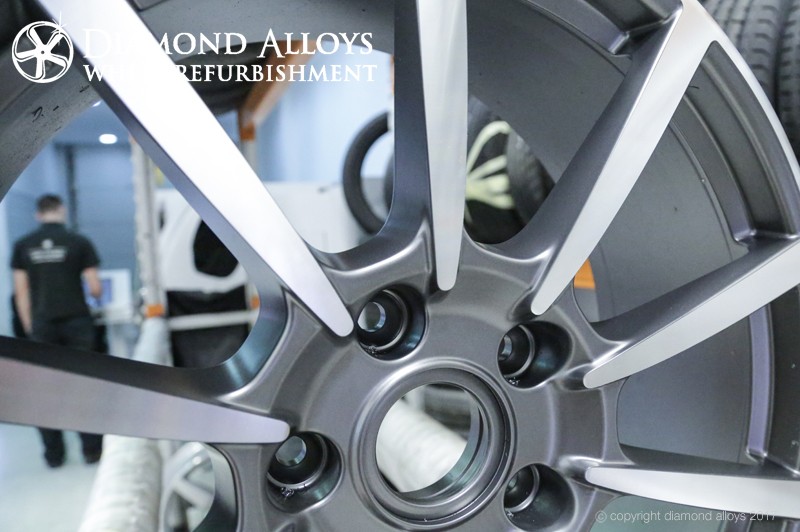

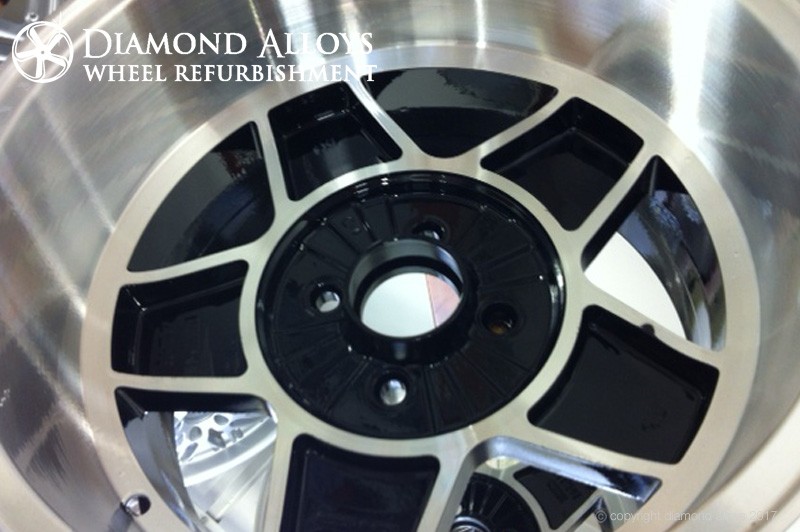

Our diamond cut alloy service enables a range of different visual styles to be created. Combining this with painted, customised inserts enables each customer to create a unique aesthetic. Our experienced technicians will be on hand to explain the various options.

A Stunning High-Quality Finish

Our experts can deliver a stress free, high quality diamond cut alloy repair service, utilising precision machine cutting to deliver excellent results and a stunning appearance.

Factors such as scrapes and chippings from the road and collisions with the kerb can leave your wheel trims looking tired and damaged, but our diamond cut alloy repair service can restore them. It is not available for all alloys, but our experts will be able to explain if it can be done for your particular alloys. If you’d like to know more, please get in touch today.

Looking After Your Diamond Alloys

Looking after diamond cut alloy wheels is a specialised issue. We recommend cleaning them a minimum of twice a week, using a car sponge and some wheel cleaner.

It’s possible that water can seep into your wheels and cause damage. The good news is that our expert technicians can re-service your alloys whenever needed. One of the tell-tale signs of water seeping under the lacquer is the appearance of milky patches. If you spot signs such as this, please contact us for an explanation of how further damage could be prevented.

Diamond Cutting – How it Works

Each wheel we work on is put through a highly defined diamond cut alloy service which involves cleaning each wheel before applying powder coating, paint, diamond cutting and lacquer. The end result is alloys which look perfect and stay that way for a long time.

1.The Wheels Come at Alloy Wheel Repair London Workshop

Wheels can be dropped off by customers or we can collect them ourselves. Once they arrive, the tyres will be removed using specialist equipment. Identifying marks are applied, and the tyres safely stored.

We check the alloys for stress fractures, buckles or cracks, and let the customer know if they are beyond repair or not safe to drive on. At this stage we will advise whether any work besides the diamond cut wheel repair itself needs to be carried out. The next stage is to strip the weights from the wheels and mark them using tyre pressure sensor equipment to guarantee the right replacement.

2. Aquablasting

Chemicals are used to strip the alloys back to bare metal, after which aquablasting is used to remove chemicals, other impurities while keying the alloy’s surface. This part of our custom alloy wheel repair service works more quickly than other methods and delivers the best results. The next stage is for the alloys to be de-greased and carefully removal of any damage to your wheels with abrasive discs. Following this any damage to the rim edges and face will be prepared, dressed and filled to be dealt with.

3.The Diamond Cut Process

Having been cleaned, the alloy is put into a lathe, with the exact locations of damage pinpointed. This data is then fed through the machine and the diamond cutting process begins, with the cutting process slowly being moved closer to the surface of the alloy, removing an extremely fine layer of metal as it moves.

The alloys are spun at an extremely high speed, being held in place by a rotary cylinder. The extremely precise and sharp blade attached to the end of the machine has an electric mechanism beneath it, ensuring it moves extremely smoothly and that the high speeds involve don’t cause any damage.

4. Applying Lacquer and Baking

The next step of the diamond cut alloy repair process is for the alloys to be placed into state-of-the-art ovens. These provide a sealed and pressure-controlled environment. The oven then applies two layers of lacquers immediately following the cutting, protecting the alloys against future wear and tear.

5.Detailed Inspection

After 20-30 minutes the alloys will have cooled and can be inspected to ensure that the finish meets the extremely high standards.

6. Wheels are Re-fitted and Balanced

The last thing we do is fit the alloys back to the tyres, after which the wheels are balanced and are ready to be collected. We will only re-fit tyres which meet the applicable legal standards.

ll Diamond Cut Alloy Wheel Repair – Common Questions

- Are any wheels suitable for diamond cutting?

The answer to this question is no, as it depends upon the profile of the particular alloy wheel face. If you send an image of your alloy wheels to us via email, our experts will advise as to the best course of action. - What shows that my alloys have been Diamond Cut?

Diamond cut wheels will have a high shine metal section showing very faint machine lines when closely examined. In appearance, the finish will resemble the surface of a CD. - What is the length of time for the Diamond Cutting process?

Many centres take as long as 5 working days to offer this service, if not longer. The fact that we have our own specialist equipment means that we can do it in just 72 hours, depending upon the condition of the alloys. - How Long will a Diamond Cut Last?

The salt which is placed on roads in the UK means that a diamond cut finish may not last as long as others. Taking care of your wheels will prolong the lifespan, use a product such as Autoglym's Custom wheel cleaner. - What number of times can my alloys be diamond cut?

Dependent upon the individual wheel, it could be diamond cut between two to five times. If you send us your images, we’ll be able to advise about your wheels. - Does diamond cutting alloy repair come with a warranty?

Yes. At Alloy Wheel Repair London, we provide a 12-month warranty. - Is there anything else I need to know?

Having four wheels diamond cut comes with a discount.