PRODUCT DETAILS

The Split Rim Alloy Wheel Repair

Here at Alloy Wheel Repair London we have the expertise to handle a range of different issues, including split rims. The appeal of the split rim for car fans is that they create a distinctive finish and striking appearance.

Our experts work at our alloy wheel centre in London, offering powder coating and diamond cutting facilities. The combination of the two techniques can produce a visually impressive result, including the combination of high impact colour choices.

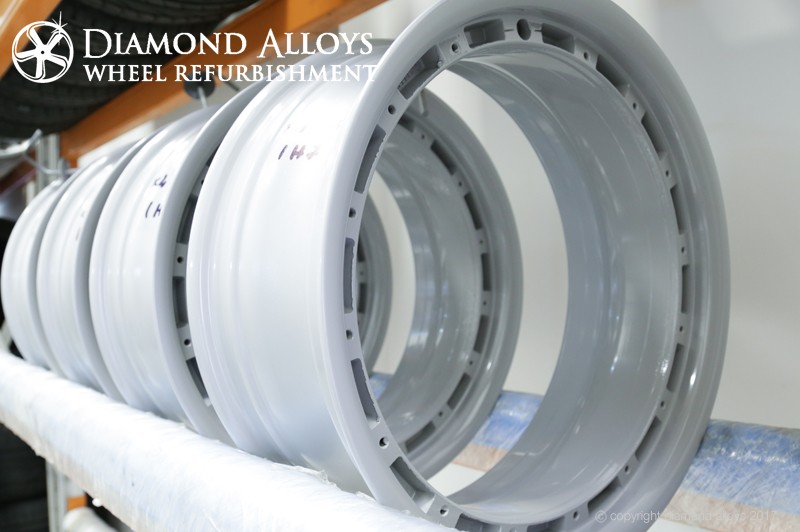

Split rim alloy wheel refurbishment is a more complex process than standard refurbishment, but also means it is possible to create your own colour palette while saving money when compared with buying new products. The separate parts of the split rim are processed on their own before being re-assembled. Our facilities enable us to work on both cosmetic split rims and actual two-piece rims. If you contact us via email to discuss your split rim alloy wheels our experts will be pleased to explain the best refurbishment options.

High Quality Split Rim Alloy Refurbishment

Our experience and expertise in the field of split rim alloy wheel repair means that all the work we do is carried out to the highest possible standard. We deliver a stress free, high quality service which guarantees great results every time.

Factors such as chippings and scrapes from the road or impact with the kerb can damage wheel trims, and our expert services can restore them to their former glory at a fraction of the price of buying new trims. Get in touch with our team of experts and we’ll explain whether the service is suited to your alloys.

Looking After Split Rim Alloy Wheels

Like other forms of refurbishment, our split rim alloy wheels need to be looked after carefully to maintain their appearance and prolong their lifespan. They should be cleaned twice a week at a minimum, using a car sponge and wheel cleaner.

It’s possible that water can seep into your wheels and cause damage. The good news is that our expert technicians can re-service your alloys whenever needed. One of the tell-tale signs of water seeping under the lacquer is the appearance of milky patches. If you spot signs such as this, please contact us on 0208 589 3020 for an explanation of how further damage could be prevented. Contact us as soon as you can for the best possible results.

Split Rim Alloy Wheels – How it Works

Each wheel we work on is put through a highly defined split rim alloy wheel repair process which involves them being cleaned, powder coated and painted. If requested a diamond cut can also be applied before lacquering takes place, to ensure the alloys look perfect and have longevity.

1. The Wheels Come at Alloy Wheel Repair London Workshop

Wheels can be dropped off by customers or we can collect them ourselves. Once they arrive, the tyres will be removed using specialist equipment. Identifying marks are applied, and the tyres safely stored. We check the alloys for stress fractures, buckles or cracks, and let the customer know if they are beyond repair or not safe to drive on. At this stage we will advise whether any work besides the buckled wheel repair itself needs to be carried out. The next stage is to strip the weights from the wheels and mark them using tyre pressure sensor equipment to guarantee the right replacement.

2. Aquablasting

Chemicals are used to strip the alloys back to bare metal, after which aquablasting is used to remove chemicals, other impurities while keying the alloy’s surface. This part of our custom alloy wheel repair service works more quickly than other methods and delivers the best results. The next stage is for the alloys to be de-greased and carefully removal of any damage to your wheels with abrasive discs. Following this any damage to the rim edges and face will be prepared, dressed and filled to be dealt with.

3. Powder Primer is Applied

The alloys being worked on are then placed in an oven and heated for 30 minutes. This removes any air trapped in the microscopic pores, so that no air escapes as the paint is being applied, something which would reduce the quality of the finish. Powder primer is now applied to every side of each section and the alloys are reheated to make sure that the powder primer is cured, to produce a high strength, hard wearing coating.

4. Colour is Applied

What happens next is that the colour of your choice is applied to the alloys. Many clients opt for a shade of silver, but the possibilities are virtually endless. The paint we use is that which is supplied to the leading European wheel manufacturers, guaranteeing a superb colour match and quality.

5. Final Coating, Cooling and Checking

The final coat of lacquer is then applied to the alloys before they are baked. This process makes the wheels extremely durable and able to cope with the elements. After being baked, the alloy sections are hung up to cool for approximately 20-30 minutes, before being inspected to check that they meet our extremely high standards.

6. Tyres are Re-fitted and Balanced

The last thing we do is reassemble the split rim and refit the tyres, before balancing the wheels and, if possible, resetting any tyre pressure system. Following this the wheels are ready to be collected.

Please note that we will not refit illegal tyres.

Split Rim Alloy Wheel Refurbishment – Common Questions

- Can all split rims be refurbished?

Although we can refurbish and repair cosmetic split rims and two-piece split rims, we can’t repair badly cracked alloys for reasons of safety. If you email us a picture of your alloy wheels our experts will be able to advise on the best course of action. - How long does the process take?

We do all the work on split rim wheel refurbishment in-house, so we can turn custom alloy wheels around in just 72 hours. The specialist and very intricate nature of the process means that it does take a little longer than standard refurbishment. Your alloys can be dropped with us, or we’ll come and collect them. - How long does a split rim refurbishment last?

Our custom repairs are guaranteed for a period of 12 months but look after them properly and they will last much longer. - How many times can a set of alloys be repaired?

The answer to this depends upon the nature of the alloys and how badly damaged they are. Get in touch with details and some images and our experts will provide the advice you need.. - Is there anything else I need to know?

We offer a discount when repairing four wheels.